How sulfur could be a surprise ingredient in cheaper, better batteries

The key to building less-expensive batteries that could extend the range of EVs might lie in a cheap, abundant material: sulfur.

Addressing climate change is going to require a whole lot of batteries, both to drive an increasingly electric fleet of vehicles and to store renewable power on the grid. Today, lithium-ion batteries are the dominant choice for both industries.

But as the need for more batteries grows, digging up the required materials becomes more challenging. The solution may lie in a growing number of alternatives that avoid some of the most limited and controversial metals needed for lithium-ion batteries, like cobalt and nickel.

One contender chemistry, lithium-sulfur, could soon reach a major milestone, as startup Lyten plans to deliver limited quantities of lithium-sulfur cells to its first customers later this year. The cells (which can be strung together to build batteries of different sizes) will go to customers in the aerospace and defense industries, a step on the journey to building batteries that can stand up to the test of EVs.

When it comes to new options for batteries, “we need something that we can make a lot of, and make it quickly. And that’s where lithium-sulfur comes in,” says Celina Mikolajczak, chief battery technology officer at Lyten.

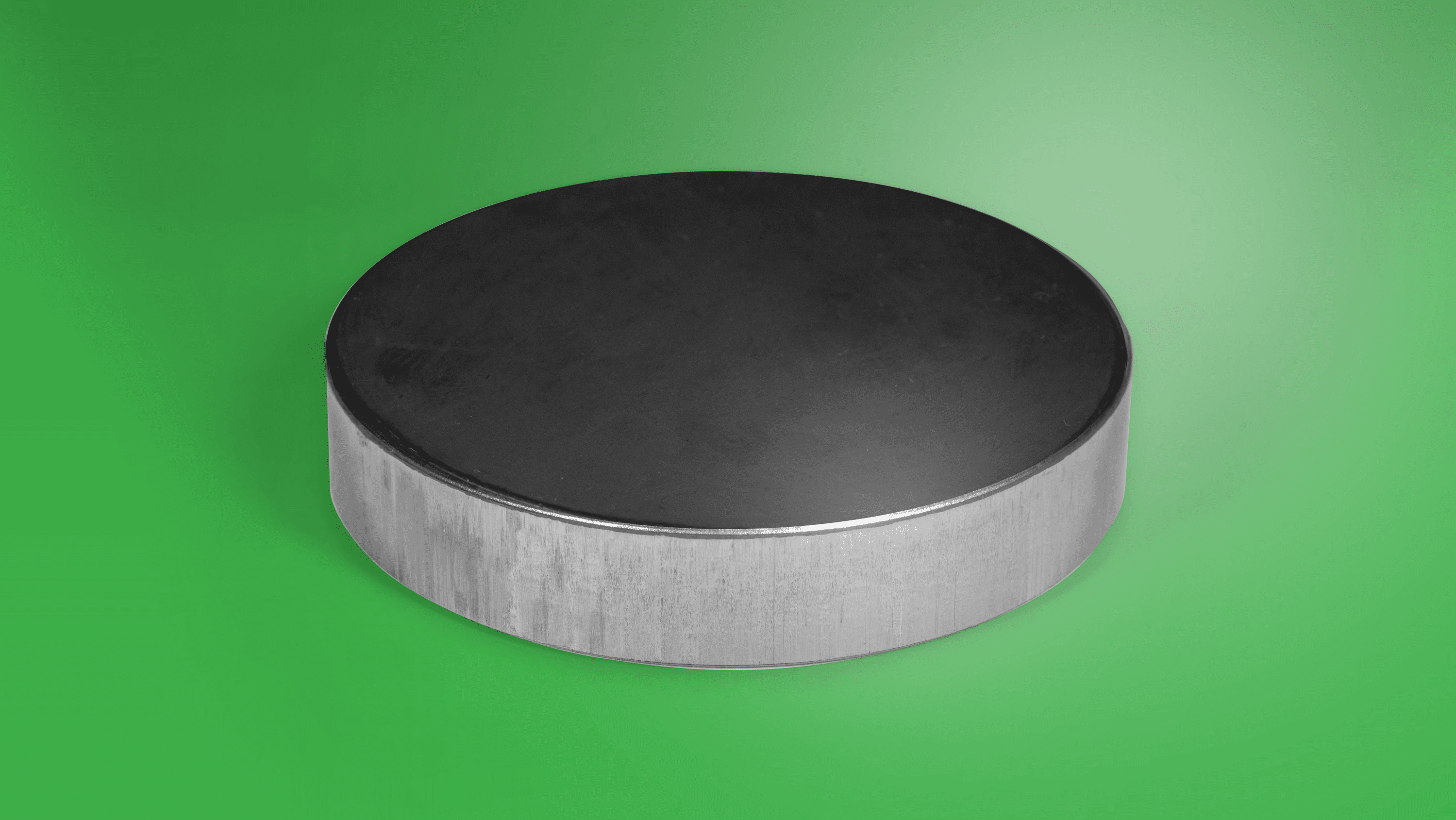

Sulfur is widely abundant and inexpensive—a major reason that lithium-sulfur batteries could come with a much cheaper price tag. The cost of materials is around half that of lithium-ion cells, Mikolajczak says.

That doesn’t mean the cost for the new batteries will immediately be lower, though. Lithium-ion has had decades to slowly cut costs, as production has scaled and companies have worked out the kinks. But a lower cost of materials means the potential for cheaper batteries in the future.

Not only could lithium-sulfur batteries eventually provide a cheaper way to store energy—they could also beat out lithium-ion on a crucial metric: energy density. A lithium-sulfur battery can pack in nearly twice the energy as a lithium-ion battery of the same weight. That could be a major plus for electric vehicles, allowing automakers to build vehicles that can go farther on a single charge without weighing them down.

However, there are still major technical barriers Lyten needs to overcome for its products to be ready to hit the road in an EV. Chief among them is getting batteries to last.

Today’s lithium-ion batteries built for EVs can last for 800 cycles or more (meaning they can be sapped and recharged 800 times). Lithium-sulfur options tend to degrade much faster, with many efforts today hovering somewhere around 100 cycles, says Shirley Meng, a battery researcher at the University of Chicago and Argonne National Laboratory.

That’s because taming the chemical reactions that power lithium-sulfur batteries has proved to be a challenge. Unwanted reactions between lithium and sulfur can sap the life out of batteries and drive them to an early grave.

Lyten is far from the first to go after the promise of lithium-sulfur batteries, with companies big and small making forays into the chemistry for decades. Some, like UK-based Oxis Energy, have shuttered, while others, including Sion Power, have pivoted away from lithium-sulfur. But growing demand for alternatives, and a higher level of interest and funding, could mean that Lyten succeeds where earlier efforts have failed, Meng says.

Lyten has made progress in stretching the lifetime of its batteries, recently seeing some samples reach as high as 300 cycles, Mickolajczak says. She attributes the success to Lyten’s 3D graphene material, which helps prevent unwanted side reactions and boost the cell’s energy density. The company is also looking to use 3D graphene, a more complicated structure than the two-dimensional variety, in other products like sensors and composites.

Even with recent progress, Lyten is still far from producing batteries that can last long enough to power an EV. In the meantime, the company plans to bring its cells to market in places where lifetime isn’t quite so important.

Since lithium-sulfur batteries can be extremely lightweight, the company is working with customers building devices like drones, for which replacing the batteries frequently would be worth the savings on weight, says Keith Norman, Lyten’s chief sustainability officer.

The company opened a pilot manufacturing line in 2023 with a maximum capacity of 200,000 cells annually. It recently began producing a small number of cells, which are scheduled for delivery to paying customers later this year.

The company hasn’t publicly shared which companies will receive the first batteries. Moving forward, two of the company’s main focuses are improving lifetime and scaling production of both 3D graphene and battery cells, Norman says.

The road to lithium-sulfur batteries that can power EVs is still a long one, but as Mikolajczak points out, today’s staple chemistry, lithium-ion, has improved leaps and bounds on cost, lifetime, and energy density in the years that companies have been working to tweak it.

People have tried out a massive range of chemistry options in batteries, Mikolajczak says. “To make one of them reality requires that you put in the work.”